Every year, we invest a large amount as R&D funds.We always take the research and development of new products and new technologies as the top priority of our company’s operation.Our R&D engineers have mastered a lot of skills and experiences, We provide these R&D customized production services for customers.

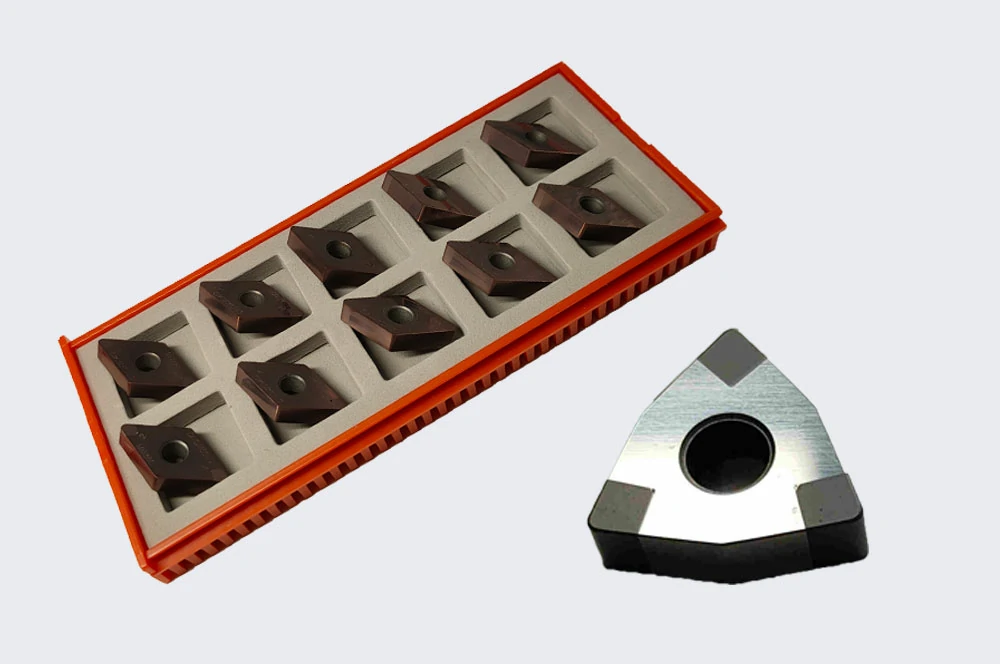

SCBN Tools SBH series pcbn inserts are tipped cbn tools independently produced and developed with the help of the parent company's raw material advantages, have excellent impact resistance, stability and super wear resistance, and can keep high tool life under the condition of ensuring the quality of the workpiece. Processing condition can include: continuous cutting-medium interrupted machining-heavy interrupt turning. SBH series cbn inserts have excellent cost-performance, compared with other pcbn tools, can perform as good as Sandvik, Sumitomo and other international pcbn tools, and the price is lower, is the best choice for currently most cost-effective product.

INQUIRE

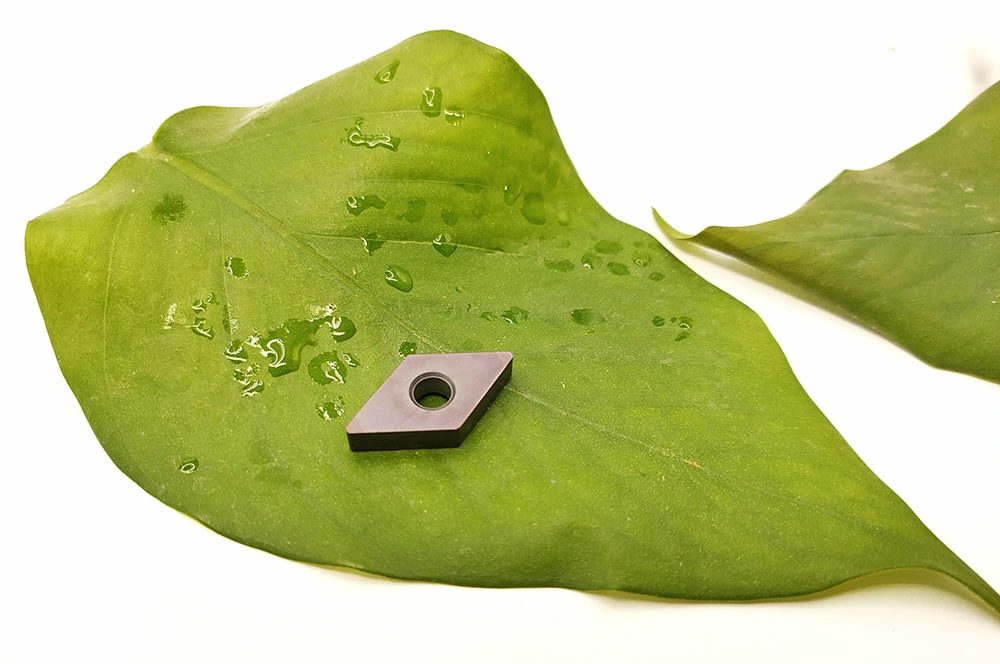

S6000A\S6000T nano-coating is made by the most advanced and environmentally friendly nano-materials independently developed by SCBN TOOLS, so that SCBN TOOLS products have world-class competitiveness. The coating has the advantages of high strength, high hardness, low friction coefficient, low thermal conductivity, corrosion resistance, insulation, etc. It is a revolutionary breakthrough in CBN tool coating. SCBN TOOLS has a number of coating patents, we have invested heavily to set up a complete R&D center to ensure that the coating cost can be effectively controlled and the stability of long-time use can be maintained. Compared with the uncoated CBN tool, the CBN tool with S6000A\S6000T nano-coating has a 35%-60% increase in tool life (depending on the working conditions and processing environment), is the best choice for improving tool life and stability.

INQUIRE

SBK series inserts are welded PCBN inserts based on solid materials, have high welding strength, balanced wear resistance and impact resistance. Suitable for cutting depth <2mm, processing conditions include: continuous cutting-medium interrupted machining- heavy interrupted turning, suitable for semi-finishing and finishing process. It is a cost-effective series products and a balanced choice of cost and life in replaced of cemented carbide inserts.

INQUIRE

SBN series cubic boron nitride tools cutting performance is very excellent. It is not only can competent for the processing of difficult-to-cut materials, improve productivity, but also conducive to strictly controlling the shape and dimensional accuracy of the workpiece and can effectively improve the surface quality of the workpiece, replaced grinding process. Therefore, improved the fatigue strength of the parts, prolonged the service life, and increased the reliability. Solid CBN inserts are often used for roughing and semi-finishing of bearings. Compared with carbide inserts , solid CBN inserts can complete a large margin cutting allowance. It not only improves the processing efficiency, but also reduces the processing cost of a single workpiece.

INQUIRE