Current Status of International brake disc processing tools

In the past, there were roughly two options for machining cutting tools for brake discs. The specific advantages and disadvantages are as follows:

Processing procedures: Rough machining, Semi-finishing and finishing are completed on two machine tools respectively

Disadvantages: Double clamping, low processing efficiency, difficult to guarantee processing accuracy, low cutting efficiency of carbide coated blades, poor surface finish of brake disc, large cutting resistance, stress on the surface of castings, and large dimensional fluctuations.

Processig procedure: Rough machining and finishing machining are completed on two machine tools respectively

Disadvantages: Double clamping, low processing efficiency, difficult to guarantee processing accuracy, PCBN welding blade, complex installation and adjustment of the tool tip, multiple adjustments to the tool, difficult to guarantee the processing accuracy of the brake surface.

With the popularization of more and more high-power and high-rigidity brake disc CNC production lines, and equipped with precision indexable CBN Inserts, the processing and manufacturing of brake discs can completely realize "roughing and finishing integration" processing, that is, one clamping, braking Disc rough turning, semi-finish turning, and finish turning can be completed continuously at one time, which greatly improves the production and processing efficiency of brake discs!

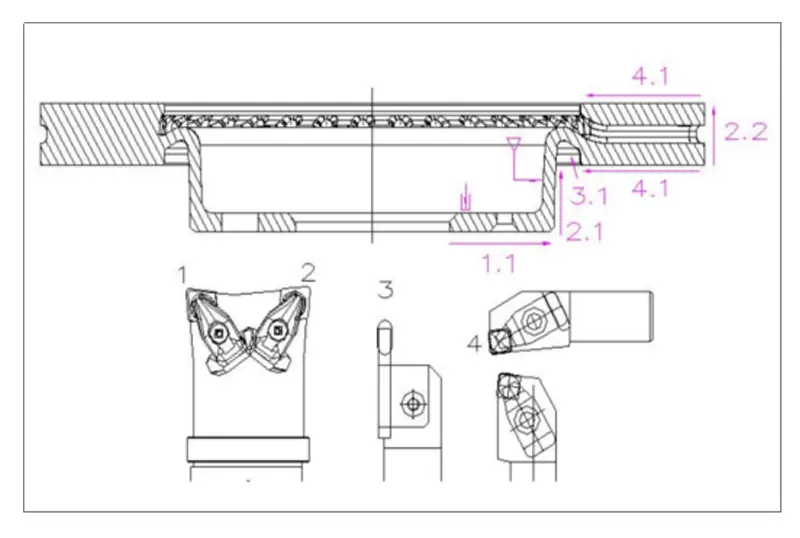

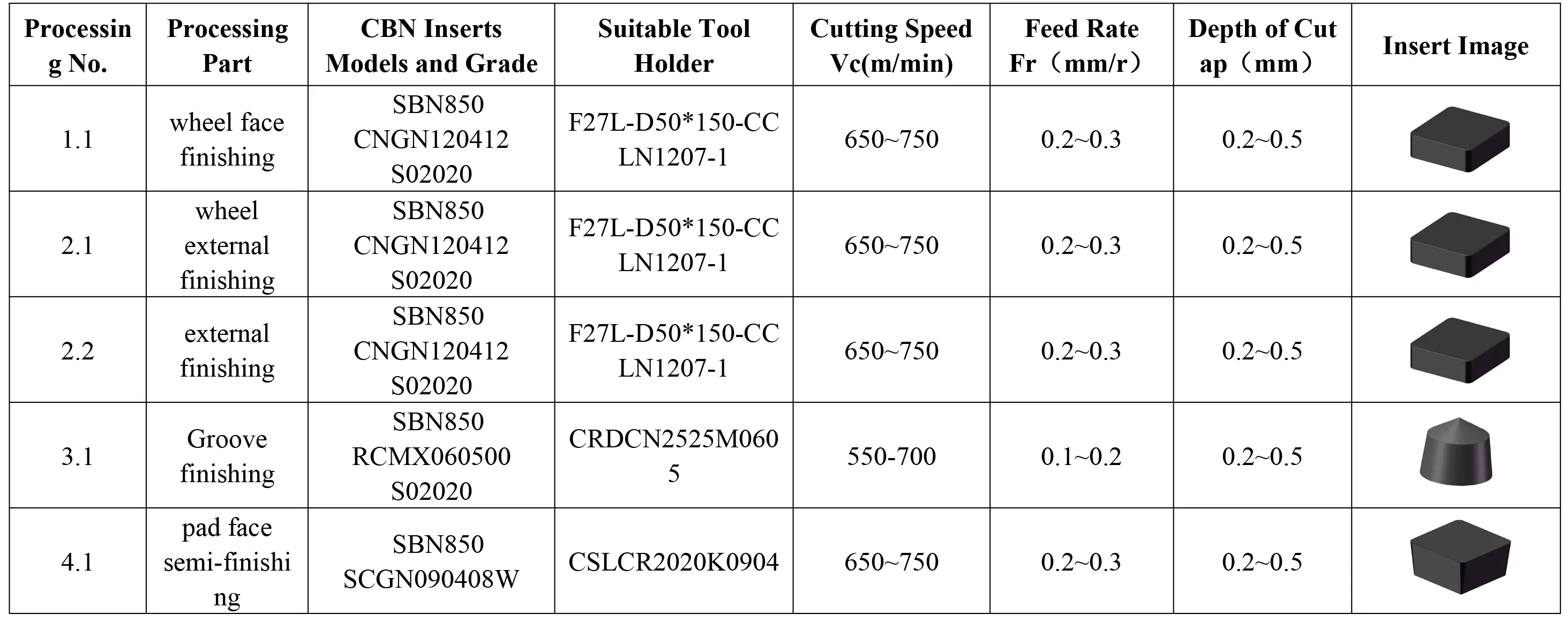

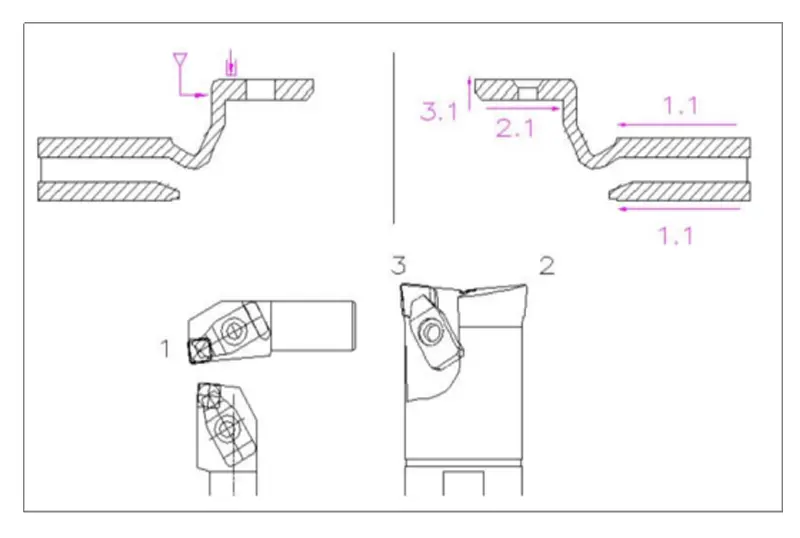

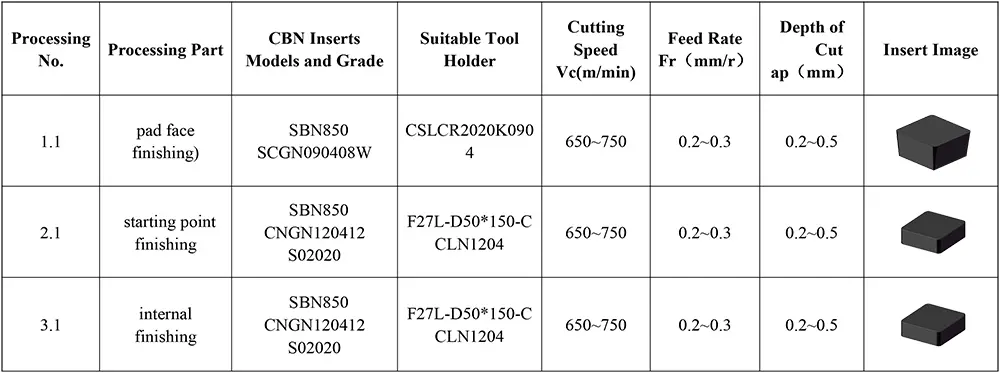

Current advanced brake disc processing scheme

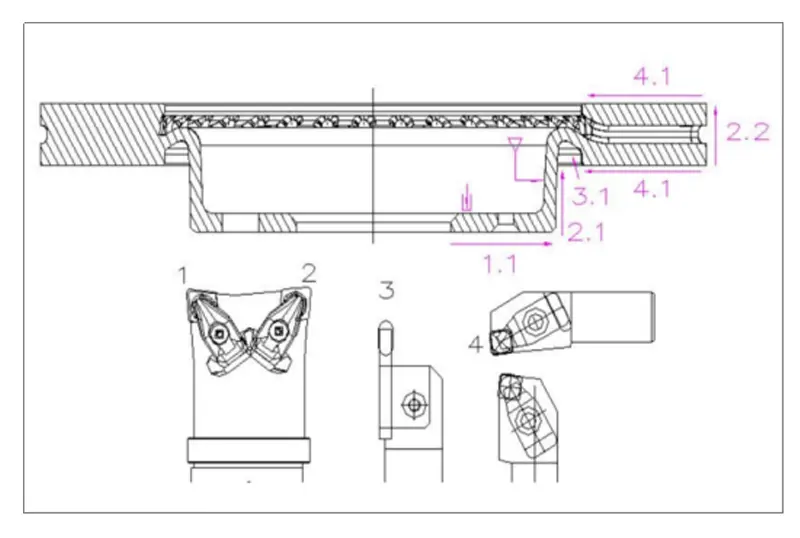

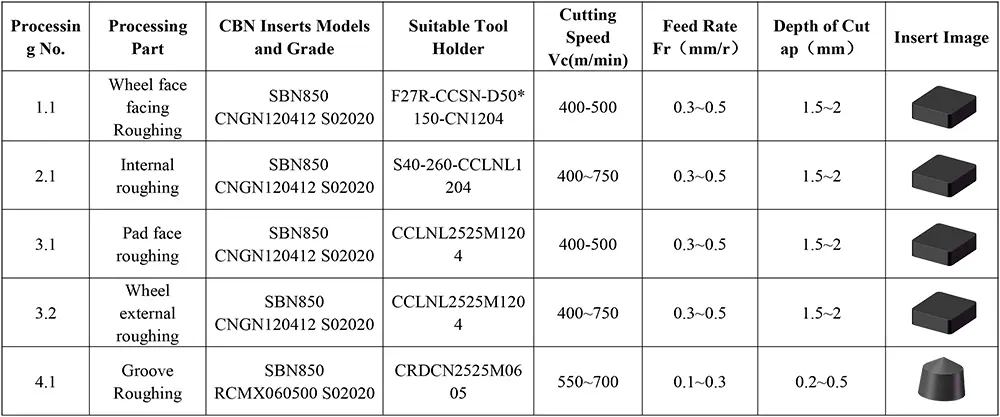

Third Process

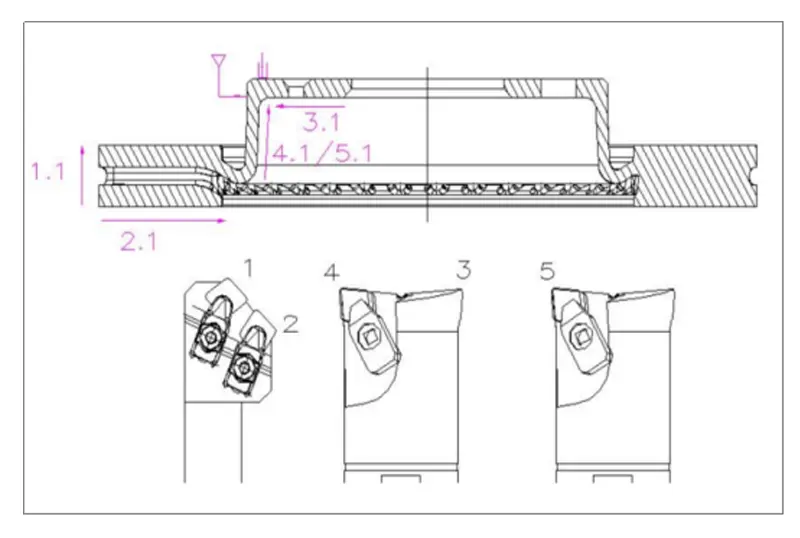

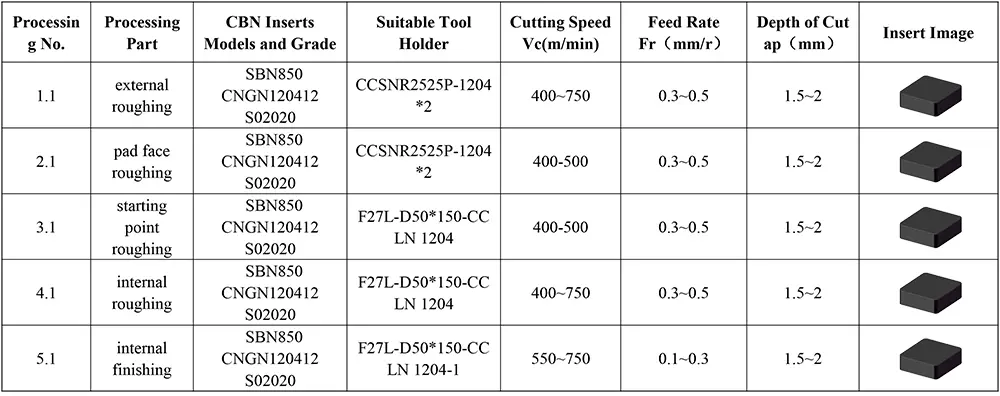

Forth Process

The processing effect of using this program CBN Insert to process the brake disc

1. Processing Efficiency

1) The Solid CBN Insert is more suitable for high-speed, high-feed, and deep-cut processing

2) The Solid CBN Insert is processed in one rough and fine process, with less processing steps, less tool change times, shortened processing time, and greatly improved processing efficiency.

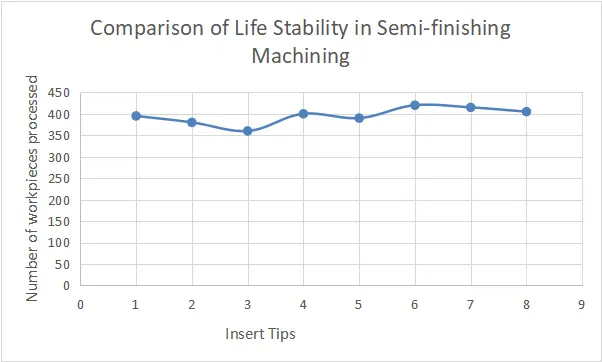

2. Tool Life

1) The CBN insert SBN850 has good wear resistance, long service life, and higher precision of the workpiece, which lays the foundation for higher precision and more stable cutting in finishing;

2) Solid CBN Insert realizes high-speed cutting, reduces the frequency of tool change, and greatly improves the processing efficiency.

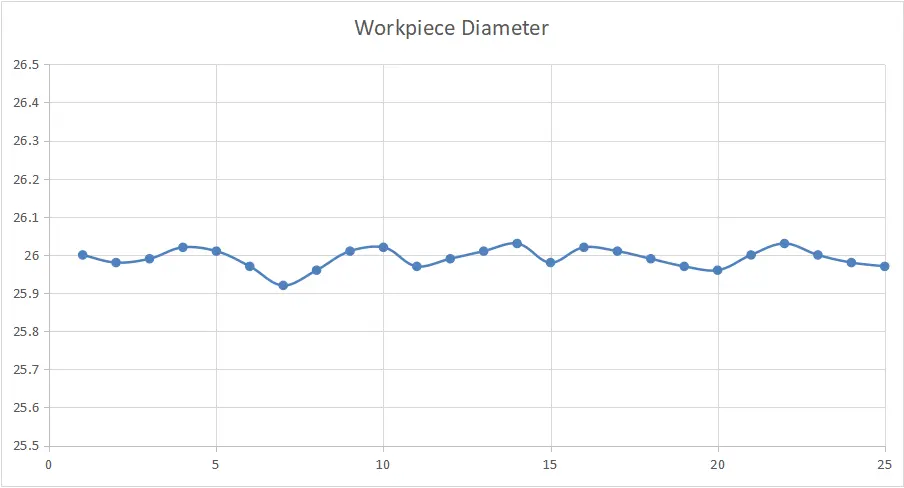

3. The Brake Disc precision

1)The brake disc adopts this processing scheme, the cutting force is small in the whole processing process, and the internal stress of the brake disc is small, so that the size fluctuation of the brake disc after finishing is reduced;

2) SBN850 Solid CBN Inserts have a long service life and good indexability, which ensures the dimensional stability and parallelism of the brake disc brake surface, making the running process of the car more stable and the braking performance better.

In Conclusion

At present, most domestic and international brake disc manufacturers have realized fully automated production. CBN inserts are very mature in this processing field, and have successfully replaced alloy coated inserts and ceramic inserts, becoming the mainstream tool in the brake disc processing industry. If some end users use ceramic blades in various forms and are unwilling to change the tool holder, we can also provide customized services. The following are commonly used positioning pits, and other forms can also be customized according to customer needs.