Quenched Steel Machining Solutions

(1) High hardness, high strength, and almost no plasticity: This is the main processing feature of hardened steel. When the hardness of quenched steel reaches HRC50-60, its tensile strength Rm is 2100-2600MPa, which is the most difficult material to process, and general YT726 alloy tools or ceramic tools cannot be moved. In the heat treatment deformation problem, the depth of the tool is uneven, and the phenomenon of chipping is easy to occur.

(2) Large cutting force and high cutting temperature: To cut chips from a workpiece with high hardness and high strength, the unit cutting force Kc can reach 4500MPa, and the cutting temperature is more than 50% higher than that of general steel. In order to improve the cutting conditions and increase the heat dissipation area, the tool selects a smaller main declination angle and secondary declination angle. At this time, vibration will be caused, and better rigidity of the process system is required.

(3) It is not easy to generate built-up edge: quenched steel has high hardness and brittleness, and the cutting temperature is higher than the conditions for generating built-up edge, so it is not easy to generate built-up edge during turning, and the machined surface can obtain a lower surface roughness.

(4) The cutting edge is easy to break and wear: due to the brittleness of hardened steel, the contact between the turning chips and the cutting edge is short, and the cutting force and cutting heat are concentrated near the cutting edge, which is easy to break and wear the cutting edge. The machined surface of many hardened steels has intermittent cutting, such as oil holes or keyways, which undoubtedly creates trouble again for cutting;

(5) Low thermal conductivity: The thermal conductivity of general quenched steel is 7.12W/(m/K), which is about 1/7 of No. 45 steel. Due to the low thermal conductivity of hardened steel, it is difficult for the cutting heat to be carried away by the chips, which accelerates the tool wear. After heat treatment, the hardness is not uniform. When turning with ordinary tools, it is easy to appear non-wear-resistant and the tool wears quickly;

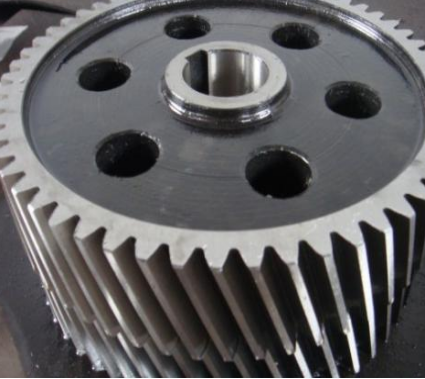

Common hardened steel parts include gears, bearings, wind power bearings, wheel hub bearings, gear rings, ball screws, ball screws, synchronizers, universal shaft connectors, etc.

Common hardened steel materials are: modulated steel, hardened steel, bearing steel, gear steel, 45# steel after quenching, SiCr, T8, T10, H13 hardened tool steel, carburized hardened steel, 20CrMnTi, 20Cr, modulated steel, 40Cr , 42CrMo hardened steel, Cr12MoV die steel, GCr15 bearing steel, 45# steel, Cr12, 8620H, 20CR, 20CRMNTI, 20MN2TIB, 20MNVB, 18CR2NI4WA, 20CR2NI4A, SKD11, etc.

SBH series is developed for hard steel parts. It can cut all hardened steels above HRC45, tool steels, die steels, high-speed steels, spring steels, carburized steels, high manganese steels, wear-resistant steels, etc. On behalf of grinding hardened steel, the effect is very significant.

1. Continuous finishing of hardened steel gears - CNGA120408

SBH130 cbn grade are recommended to achieve high-speed cutting, which increases the life of CBN inserts by 40%, thereby reducing the processing cost of a single workpiece.

Case details:

Workpiece material: 20CrMnTi (hardness HRC58~62)

Insert model: SBH130 (coated) CNGA120408

Cutting parameters: VC=180m/min, Fr=0.1mm/r, ap=0.1mm

Processing method: dry cutting

SBH150 (coated) grade CBN is mainly used in the continuous finishing process of hardened steel, to ensure the machining accuracy of the workpiece, and at the same time to improve the tool life.

2. Slightly interrupted finishing hardened steel gear - SBH170 CCGW09T304

SBH170 grade is recommended, which can withstand the slight intermittent impact of the keyway during hard turning, and can ensure the stability of turning instead of grinding on the premise of the stability of the machine tool.

Case details:

Workpiece material: 20CrMnTi (hardness HRC58-62)

tool model: SBH170 (coated) CCGW09T304

Cutting parameters: Vc=135m/min, Fr=0.08mm/r, ap=0.25mm

Processing method: dry cutting

SBH170 (coating) grade CBN is mainly used in the slightly interrupted finishing process of hardened steel, which can ensure the machining accuracy of the workpiece, and the tool has excellent wear resistance.

3. Heavy Interrupted Finishing Hardened Steel Gear - SBH190 WNGA080404

The composite CBN insert SBH190 grade is recommended. The gears with group holes on the hard-turned end face are cost-effective and have stable cutting performance. They can replace imported tools and have higher cost-effectiveness;

Case details:

Workpiece material: 20CrMnTi (hardness HRC58-62)

Blade model: SBH190 (coated) WNGA080404

Cutting parameters: Vc=117m/min, Fr=0.1mm/r, ap=0.15mm

Processing method: dry cutting

SBH190 (coated) grade CBN is mainly used for heavy intermittent finishing of hardened steel, which can ensure the machining accuracy of the workpiece, and the tool has excellent wear resistance and anti-breakage resistance.