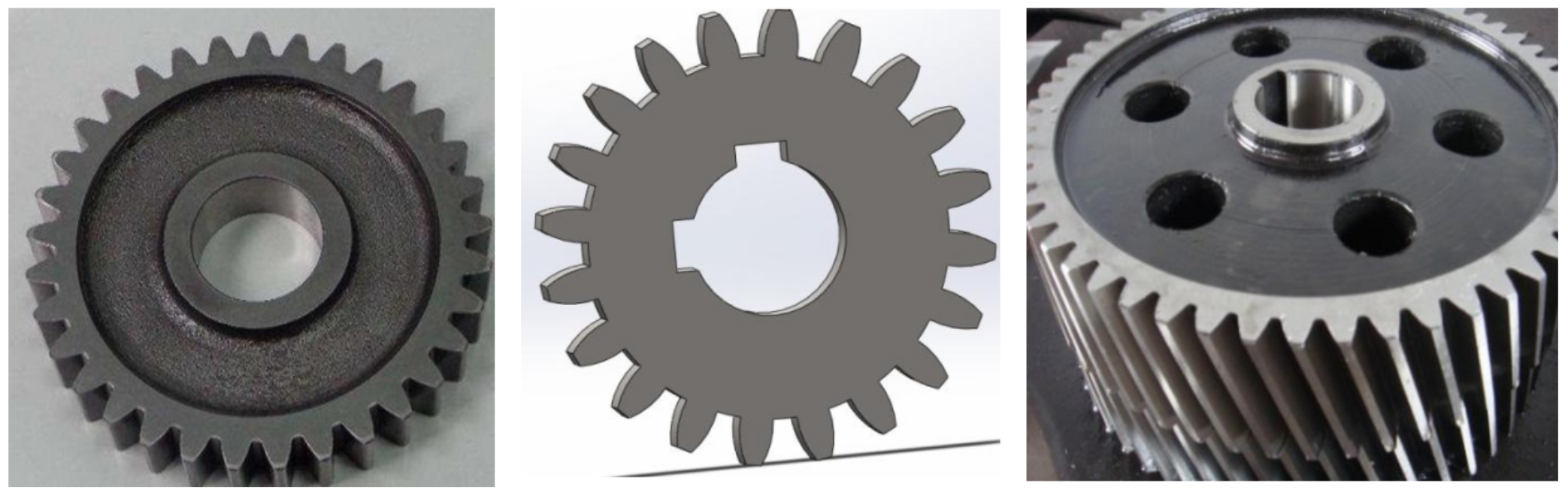

Gears are an important part of automobile transmission. The product strength, precision and fatigue life of gears have high requirements. Therefore, there are high requirements for gear materials, and at the same time, the requirements for tools are also increased. Common gear materials are: 20CrMnTi, GCr15, 42CrMo, Etc. SBCN TOOLS has developed SBH130,SBH170 and SBH190 materials for gear processing, which are respectively used for the processing of gear end face, outer circle, inner hole and tooth tip.

Continuous Finishing Gear-Inner Hole-SBH130

Processing Position: inner hole of gear

Workpiece material: 20CrMnTi, HRC58~62

Processing condition: continuous cutting

Selected tool: SBH130 CNGA120404

Cutting parameters: Vc=180m/min, ap=0.15mm, Fr=0.1mm/r

Advantages: Tool life is 4 times longer than ceramic tools for finishing gears, and the production cycle time is only 40% of ceramic tools.

Slightly interrupted finishing gear-bore-SBH170

Processing Position: gear inner hole (with keyway)

Workpiece material: 42CrMo,HRC60

Selected tool: SBH170 CCGW09T304

Cutting parameters: Vc=120m/min, ap=0.1mm, Fr=0.05mm/r

Advantages: Tool life is 8 times that of carbide tools for finishing gears, and the production cycle time is only 30% of alloy tools.