Views: Author: SCBN TOOLS Publish Time: 2022-05-30 Origin: Site

CBN inserts are becoming the norm in machine tooling and the business is growing. The article discusses the benefits of CBN and how it has changed machining over time. The use of CBN inserts in machining is the result of a long buildup. In the early days of modern machining, when water and then air were used for coolant, the tools were made from hard steels. These tools wore out quickly due to their hardness and had to be sharpened more often than would be required today. We will talk the cbn inserts for machining HSS Rolls with Heavy Duty Turning.

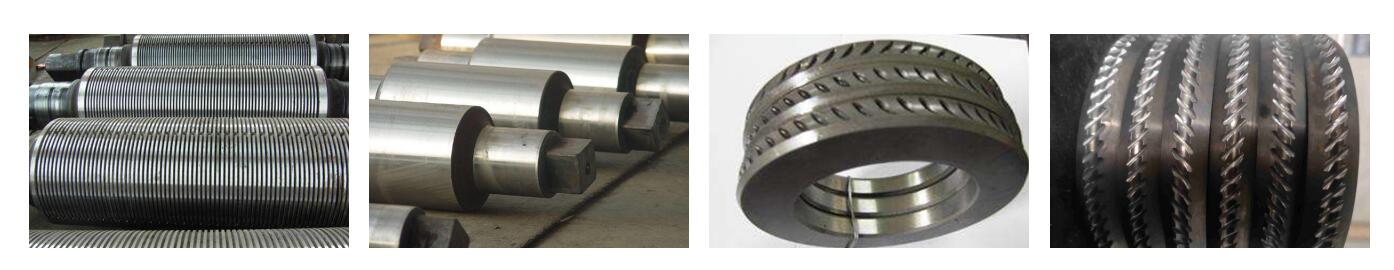

If you are looking for a versatile and mill rolls heavy duty turning solution, then Solid CBN Inserts is the perfect choice for you. These cbn inserts are made of cuibic boron nitride, making them extremely durable and long lasting. With these cbn inserts, you can achieve high quality machining results on a variety of Rolls materials, including chilled cast iron rolls, hss rolls, sprayed rolls, ect. If you want to achieve accurate and high quality cuts on your materials, then choose Solid CBN Inserts Machining HSS Rolls for unbeatable results.

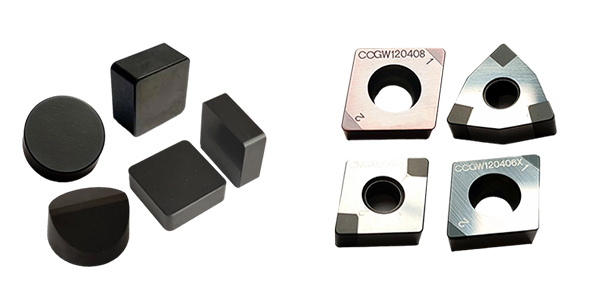

CBN inserts (Cubic Boron Nitride) is an extremely hard material that is often used for machining ferrous metals, such as hardened steel, cast iron and other high hardness materials. It is typically used in heavy duty turning applications where high cutting speeds and long tool life are required.

There are two main types of CBN inserts: solid cbn inserts and tipped pcbn inserts. Solid CBN inserts are made completely of CBN material, while tipped CBN inserts have a small portion of the cutting edge made of carbide. Tipped CBN inserts are generally used for higher speed machining, while solid CBN inserts are better suited for heavy duty turning.

Solid CBN inserts can be used for heavy duty turning of sprayed HSS rolls. This is a great option for those who are looking for a durable and long lasting insert. Solid CBN inserts are harder than most other inserts such as tungsten carbide inserts, ceramic inserts,ect. Their hardness is 6-7 on a Rockwell scale of 10. They have the ability to stay sharp for several months and can easily be resharpened later.

Solid CBN Inserts SBN850 Machining HSS Rolls

Workpiece Materials:High Speed Steel

Workpiece Hardness:HSD90

CBN Inserts Choose: SBN850 RCMX1207

Cutting Data: Fr=0.2mm/r, Vc=35m/min,ap=2.5mm

Machining Effect: Compared with Other CBN From Some European, SBN850 From SCBN Tools tool life is 2 times, and the failure mode is normal wear.

If you're looking for a high-quality and durable turning solution for your heavy-duty machining needs, then you may want to consider investing in Solid CBN Inserts Machining Sprayed HSS Rolls. These inserts are designed to offer excellent wear resistance and cutting performance, making them ideal for a variety of applications.

When it comes to choosing the right supplier for your Solid CBN Inserts Machining Sprayed HSS Rolls, there are a few things you'll want to keep in mind.

First, it's important to find a reputable and experienced company that can offer you a competitive price.

Second, you'll want to make sure that the company you're working with has a good reputation for delivering high-quality products.

Finally, it's also important to find a company that offers good customer service.

This way, if you have any questions or concerns about your purchase, you can be sure that someone will be available to help you. With these factors in mind, you should have no trouble finding the right supplier for your Solid CBN Inserts Machining Sprayed HSS Rolls needs.

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools weikejingmi