Views: Author: SCBN TOOLS Publish Time: 2023-08-10 Origin: Site

Introduction:

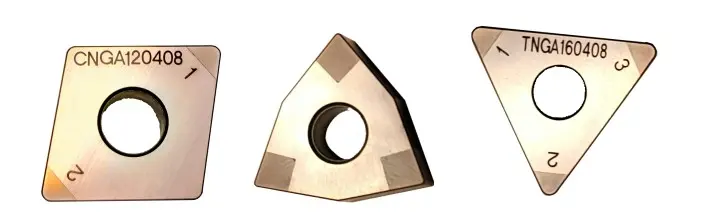

As an innovative cutting tool, the coated CBN indexable insert has greatly improved the performance and service life of the insert by introducing coated CBN technology and indexable design. This article will introduce the characteristics, advantages and wide application of coated CBN indexable inserts in cutting.

1. Features and advantages:

Coated CBN technology: Coated CBN indexable inserts adopt advanced coating technology to form a layer of CBN coating on the surface of the insert. This coating can improve the hardness and wear resistance of the tool and effectively prolong the service life of the tool.

Indexable design: The design of the indexable blade significantly improves the service life of the blade. When the blade wears or fails, the blade can be restored to normal working condition by rotating or replacing the indexable parts on the blade, which prolongs the service life of the tool.

Improve cutting efficiency: Coated CBN indexable inserts can achieve higher cutting speed and higher material removal rate through the application of coated CBN technology, and improve cutting efficiency. Compared with traditional inserts, indexable inserts have better cutting stability, reduce the frequency of tool changes and save production time.

Strong adaptability: Coated CBN indexable inserts are suitable for cutting a variety of materials, such as steel, alloy and hard materials. They can still maintain good cutting performance under high hardness and high temperature conditions, and have strong adaptability.

2. Application fields:

Coated CBN indexable inserts are widely used in cutting processes in various industries. The following are some common application areas:

Automobile manufacturing: In the processing of automotive engine parts, coated CBN indexable inserts can achieve fast and accurate cutting, improving production efficiency and quality of parts.

Aerospace: In the aerospace industry, difficult-to-machine materials such as titanium alloys and nickel-based alloys need to be cut. Coated CBN indexable inserts perform well in high temperature and high hardness conditions, providing efficient and stable cutting solutions.

Mold manufacturing: In the field of mold manufacturing, it is necessary to perform high-precision and high-efficiency cutting of hard materials. Coated CBN indexable inserts can meet the processing needs of complex molds and improve the service life of the tool.

Steel processing: In the steel industry, various types of steel materials need to be cut. Coated CBN indexable inserts can handle high hardness and high temperature cutting of steel, providing efficient and stable machining solutions.

In conclusion:

The emergence of coated CBN indexable inserts has brought revolutionary changes to cutting. By adopting coated CBN technology and indexable design, the performance of the insert has been greatly improved and the service life has been significantly extended. In the fields of automobile manufacturing, aerospace, mold manufacturing and steel processing, the excellent performance of coated CBN indexable inserts is widely used, which improves production efficiency and product quality. With the continuous advancement of technology, coated CBN indexable inserts will continue to promote the development of cutting processes and inject new vitality into industrial manufacturing.

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools weikejingmi