VBGW series inlaid composite PCBN inserts are often used as boring inserts, which can withstand continuous, intermittent and heavy interrupted machining conditions. There are different types of insert materials for cast iron and hardened steel parts, which can fully meet different customer needs.

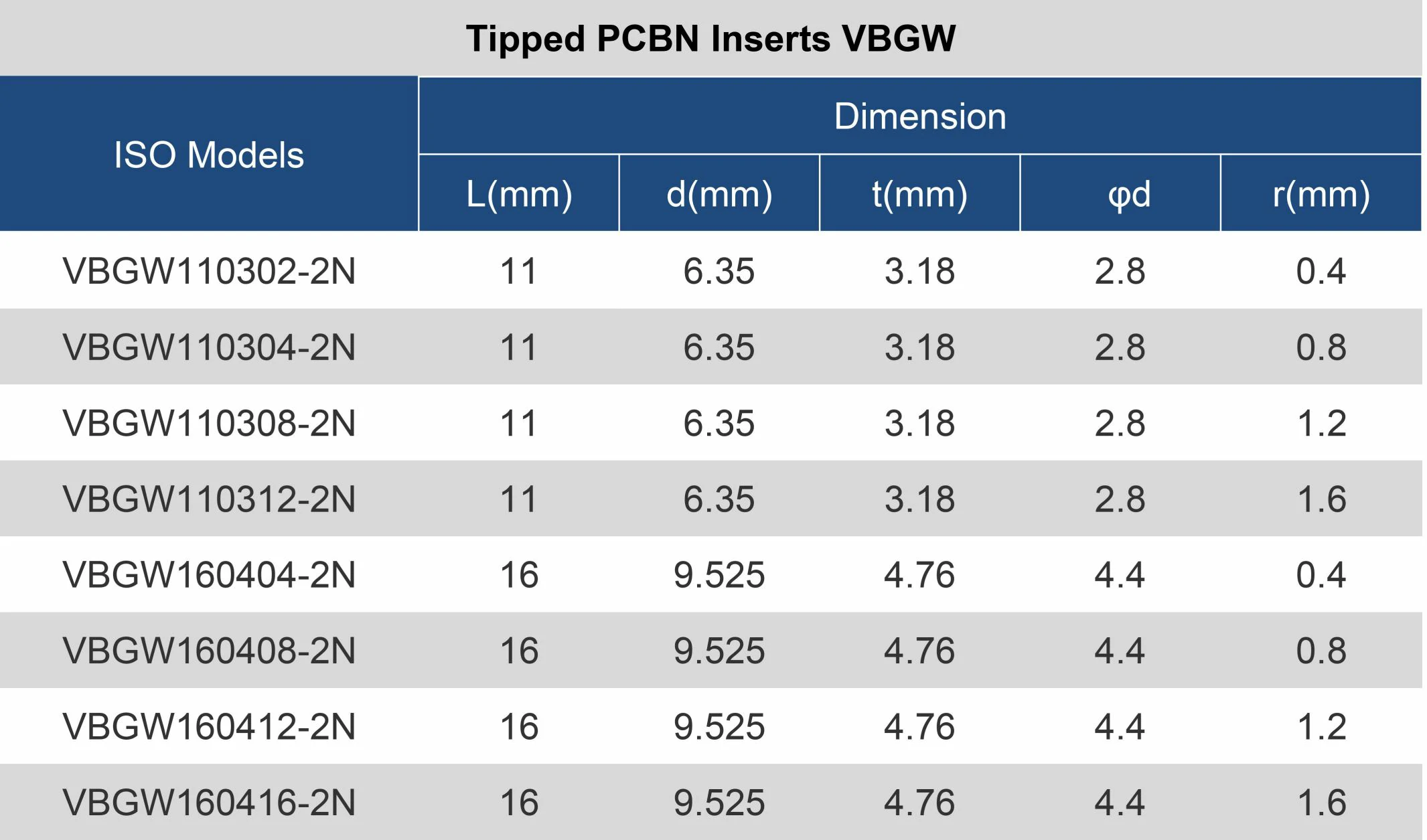

VBGW compound PCBN inserts are conventional ISO standard triangular inserts. Commonly used models are VBGW1103,VBGW1604, etc. Radius can be 02,04,08, standard inserts have 2 tips, common chamfer is S01020, S01025, S01325, ect. Other non-standard cutting edges, radius and chamfer can be customized.

VBGW composite PCBN inserts are often used for finishing and semi-finishing quenched workpiece, such as gear inner holes, gear end faces, gear outer circles and gear shafts, etc., as well as gray cast iron workpiece, such as brake discs, brake drums, engine blocks, etc.

When machining hardened steel, VBGW composite PCBN inserts can be coated. After coating, the tool life will be increased by 30%-45% compared with uncoated inserts, and the finish will also be improved.