Views: Author: SCBN TOOLS Publish Time: 2022-05-18 Origin: Site

The characteristics of hardened steel that are difficult to machine

(1) The main properties of hardened steel are high hardness and strength, and almost no plasticity. When the hardness of hardened steel reaches 50-60hrc, the tensile strength m is 2100-2600mpa, which is a difficult-to-cut material.

(2) The cutting force is large and the cutting temperature is high. In order to cut chips from workpieces with high hardness and high strength, the unit cutting force C can reach 4500mpa, and the cutting temperature is more than 50% higher than that of ordinary steel.

(3) It is not easy to produce cutting edge. Due to the high hardness and brittleness of hardened steel, the cutting temperature is higher than the conditions for generating chip build-up, so no chip build-up occurs and a lower surface roughness is obtained.

(4) The tool is easy to chip and wear. Due to the characteristics of hardened steel, the cutting force and cutting heat are concentrated near the cutting edge, which is easy to cause breakage and wear of the cutting tool.

How to choose a insert for hardened steel processing ?

Selecting a suitable machining tool is an important factor in machining efficiency and cost. According to the characteristics of hardened steel and cutting characteristics, when choosing a tool, it is necessary to choose a material with good wear resistance, high heat resistance, and certain thermal conductivity and toughness. SCBN TOOLS SBH170 and SBH190 are developed according to the processing characteristics of hardened steel. The hardness is 8000-9000hv, the heat resistance is 1400-1500℃, and the bending strength after compounding with cemented carbide is 1500MPa. It is most suitable for semi-finishing and turning of hardened steel.

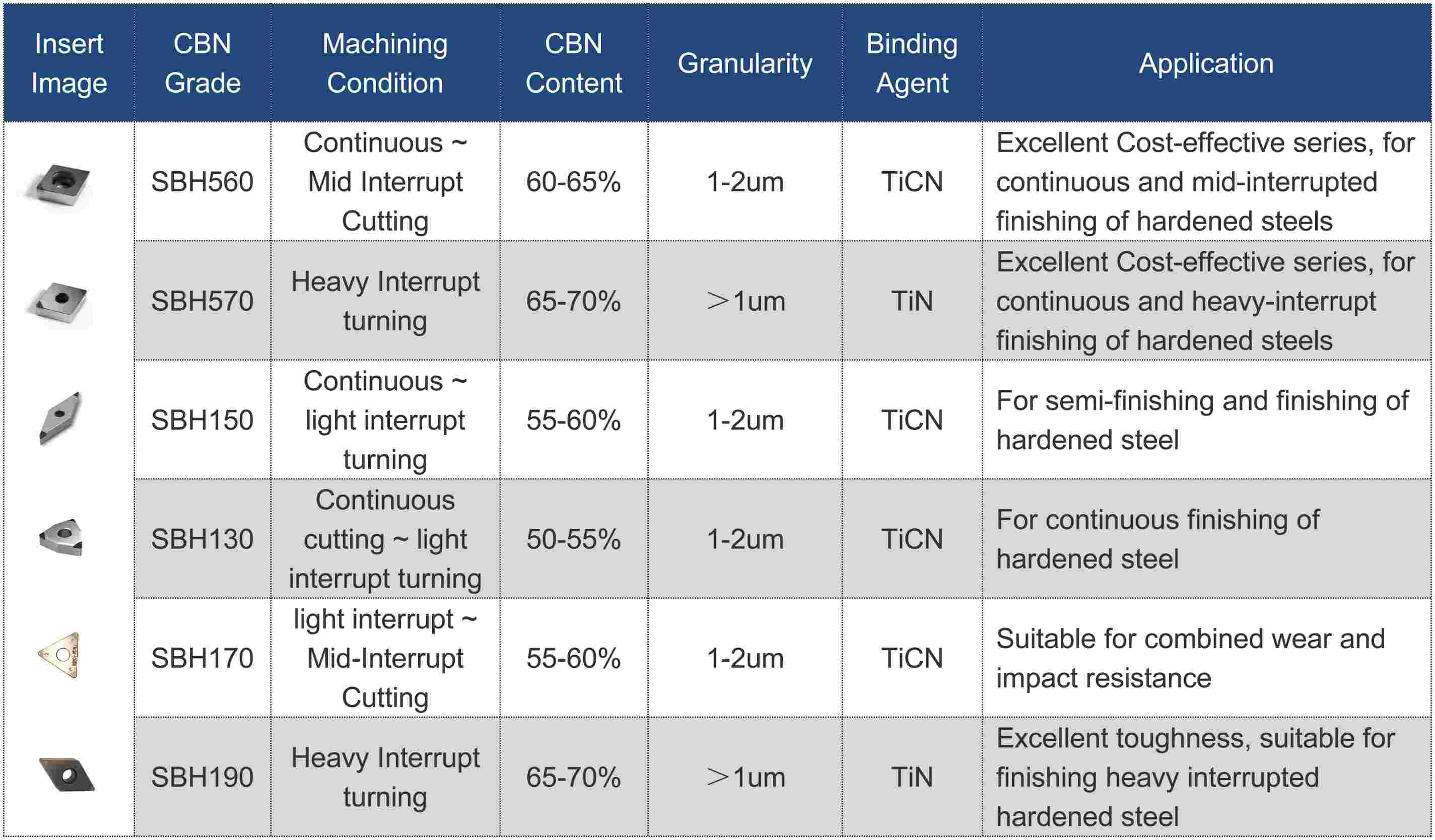

Common grades of hardened steel processing tools

Conclusion

For the processing of quenched steel, reasonable tool materials and processing parameters should be selected according to the specific processing conditions. At the same time, the use of SCBN TOOLS CBN inserts for processing can realize turning grinding, improve processing efficiency and reduce processing costs.

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools weikejingmi