Views: Author: SCBN TOOLS Publish Time: 2022-05-19 Origin: Site

Hard turning refers to the process of turning hardened steel as the final step or finishing process, instead of grinding. Hardened steel generally has high hardness. The grinding process was used before, which was very inefficient. The hard turning process greatly improved the processing efficiency.

Features of hard turning:

(1) The processing efficiency is high, and the processing time is greatly shortened compared with grinding;

(2) Dry cutting and hard turning do not need to add cutting fluid, which helps enterprises reduce costs and reduce environmental pollution;

(3) There is no need for a grinder, and the hard turning adopts the turning process instead of grinding, without separate grinders, fixtures and other tools, which helps enterprises reduce equipment costs;

Requirements for hard turning:

At present, hard turning can turn workpieces with hardness of HRC45-HRC68, and the roughness can reach Ra0.4. Therefore, the requirement of hard turning is that the workpiece material hardness must be greater than HRC45. The higher hardness of the workpiece material, the more suitable for hard turning. Common materials for hard turning are hardened steel: tool steel, die steel, carburized steel, gear steel, bearing steel after heat treatment.

Choice of hard turning inserts:

1. Coated carbide inserts: TiCN and Al2O3 coatings with good wear resistance are common. Compared with ordinary carbide inserts, the hardness is higher, the wear resistance is good, and the surface quality of the workpiece is good;

2. Ceramic Inserts: The hardness of ceramic inserts is higher than that of cemented carbide inserts, which can withstand high temperature of 2000 ° C, high hardness, high strength, high temperature chemical stability, the disadvantage is that it is brittle and cannot be cut intermittently;

3. CBN inserts: CBN inserts have higher hardness and better wear resistance than ceramic inserts and carbide inserts, and are suitable insert materials for hard turning CBN inserts. Widely used in hard turning process.

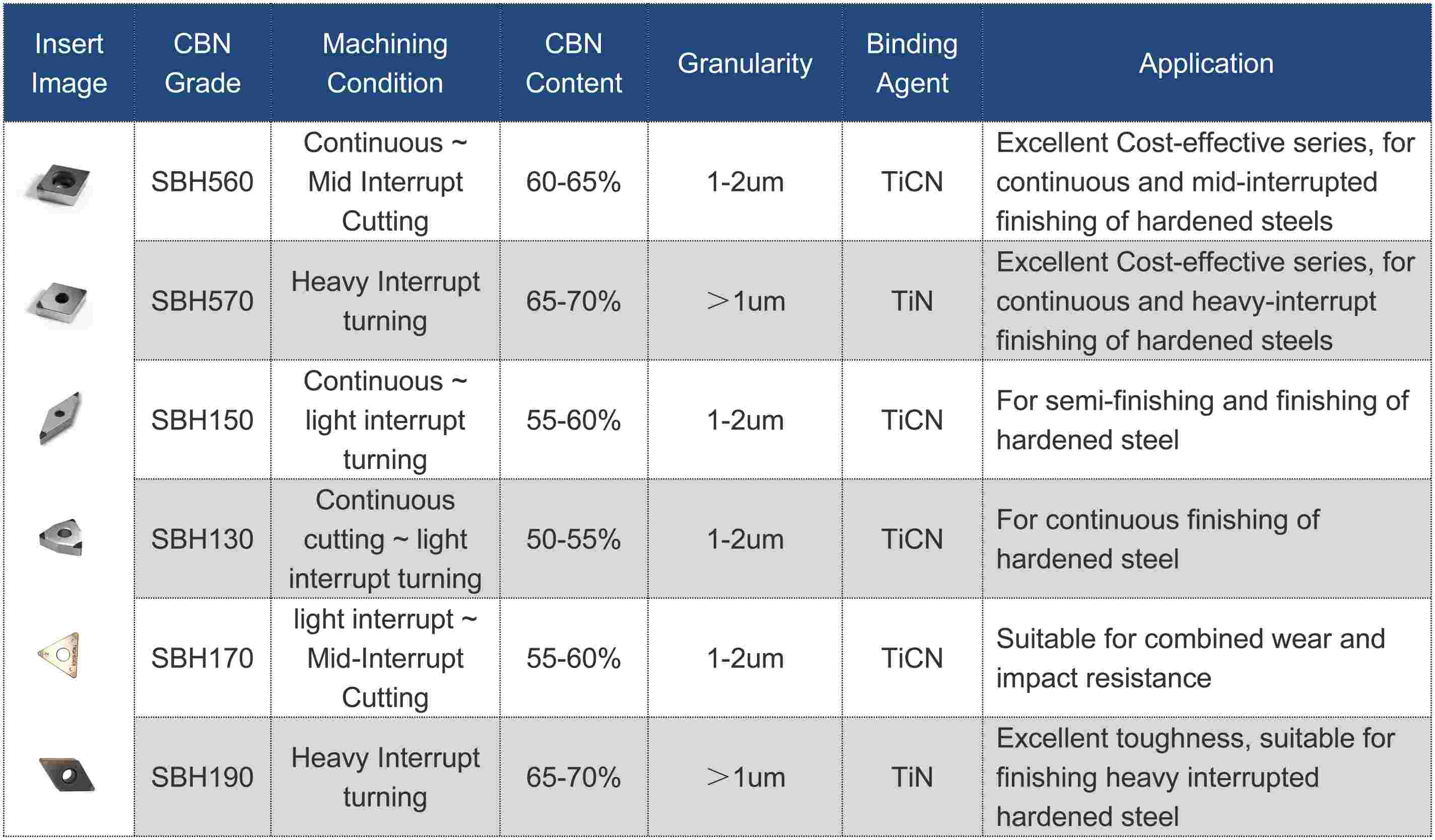

SCBN Tools commonly used CBN grades for hard turning hardened steel are:

How to choose the right blade, you can consult our tool engineer at any time.

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools weikejingmi