1. What is the PCD Inserts?

PCD Inserts (Polycrystalline Diamond Inserts) is a synthetic diamond product that produced by sintering together selected diamond particles with a metal matrix, using sophisticated technology. The diamond and matrix, when sintered together under high temperatures and pressures, creates a PCD tool blank that is high in uniform hardness and is abrasive resistant in all directions. PCD Inserts is made of PCD tips (cutting from PCD blank) and a tungsten carbide substrate.

2. Various PCD Turning Inserts Specifications

3. What materials PCD Turning Inserts can use for machining ?

4. What is the advantage of our PCD Turning Inserts?

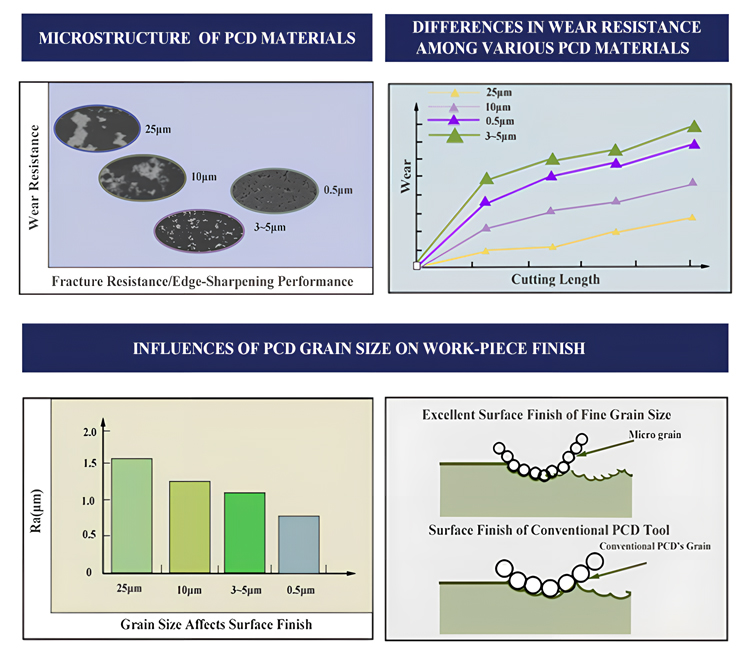

(1) Longer tool life. Due to the very high hardness of the PCD diamond, the PCD tool life can exceed carbide cutting tool life 50 to 100 times in certain applications.

(2) Higher machining efficiency. With the very sharp edge and high abrasive resistance, the PCD cutting tools can get higher cutting speed than that of tungsten carbide tools.

(3) Higher surface finish quality.

(4) Highly improved workpiece quality and excellent dimensional control.

5. What is the Application Fields of PCD Inserts?

(1) Aerospace, automotive parts processing, wind power accessories, Main Materials include composites and aluminum alloy.

(2) Wooden floor, furniture, building exterior, main materials are wood materials.

(3) Stone carving, plastic, ceramic, Main materials are stone, ceramic.