Why PCD Inserts need a chipbreaker?

PCD Inserts are generally used for single-edged continuous cutting. If chip breaking measures are not taken, the cut product will not break naturally and will be entangled with the workpiece and the tool. In this way, the surface quality of the product cannot be guaranteed, especially for some products with high surface smoothness requirements.

Moreover, the pcd inserts is easy to wear, which affects the life and processing efficiency. The cut product wire is also prone to safety accidents.

Therefore, adding a cutting groove to the PCD inserts can not only ensure product quality, processing efficiency, and tool life, but also improve the safety of the operator, achieving multiple goals at one stroke

Anvantages of PCD Chipbreaker Inserts

a) Chipbreak should be smooth without affecting normal cutting.

b) Control the volume of chips to make them easier to handle, store and transport.

c) Chips should be discharged without entanglement with workpieces, turning tools or causing failure of auxiliary devices (automatic feeders, etc.)

Standard Chipbreaker Inserts as follows:

The following is a brief introduction to PCD materials:

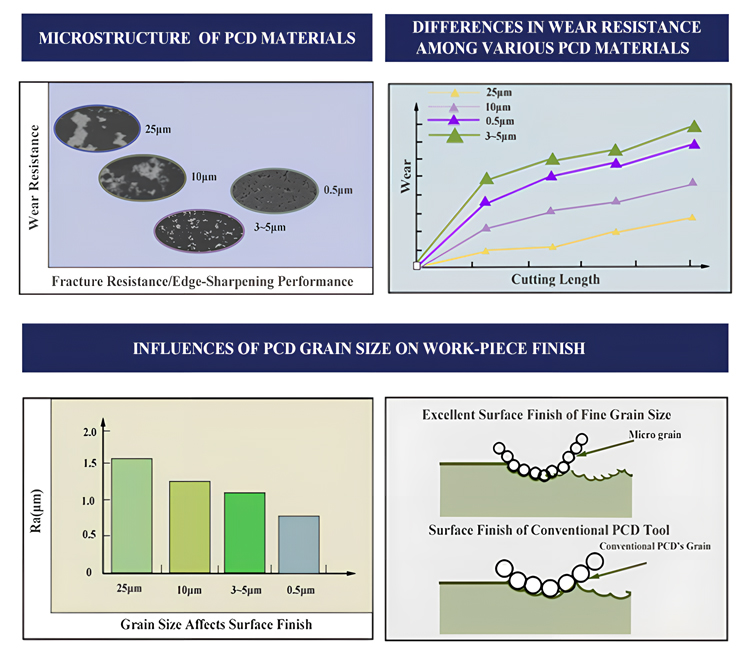

Picture 1: 25µm represents the best wear resistance and the worst fracture resistance;

Picture 2: 25µm represents the worst wear and best cutting length;

Picture 3: Grain size affects surface finish;

Picture 4: Processing surfaces with different grain sizes.

At SCBN TOOLS, all types of customized inserts are available for you.